Automatic Egg Collection System

Automatic Egg Collection System

The automatic egg collection system is used quite simply to collect eggs. It saves time and manpower, and reduces the rate of damage eggs. Using this machine reduces the egg damage rate to less than 0.1 percent. The automatic egg collection machine is suitable for 3 tier, 4 tier, and 5 tier layer cages.

Features

Features

Poultry egg collection system is suitable for large, medium and small farms, and can be customized according to user requirements to meet production needs.

The electrified machine has scientific, mechanized, automated, and intensive benefits.

Greatly improves the degree of automation, improves efficiency, and saves labor costs.

Low noise during operation, which reduces the noise influence on chickens and improves the rate of laying.

The machine runs smoothly, improving the efficiency of production.

It reduces the rate of broken eggs and increases the bottom line.

Operation of the machine is simple which saves the manpower.

It is highly wear resistant and has a long service life.

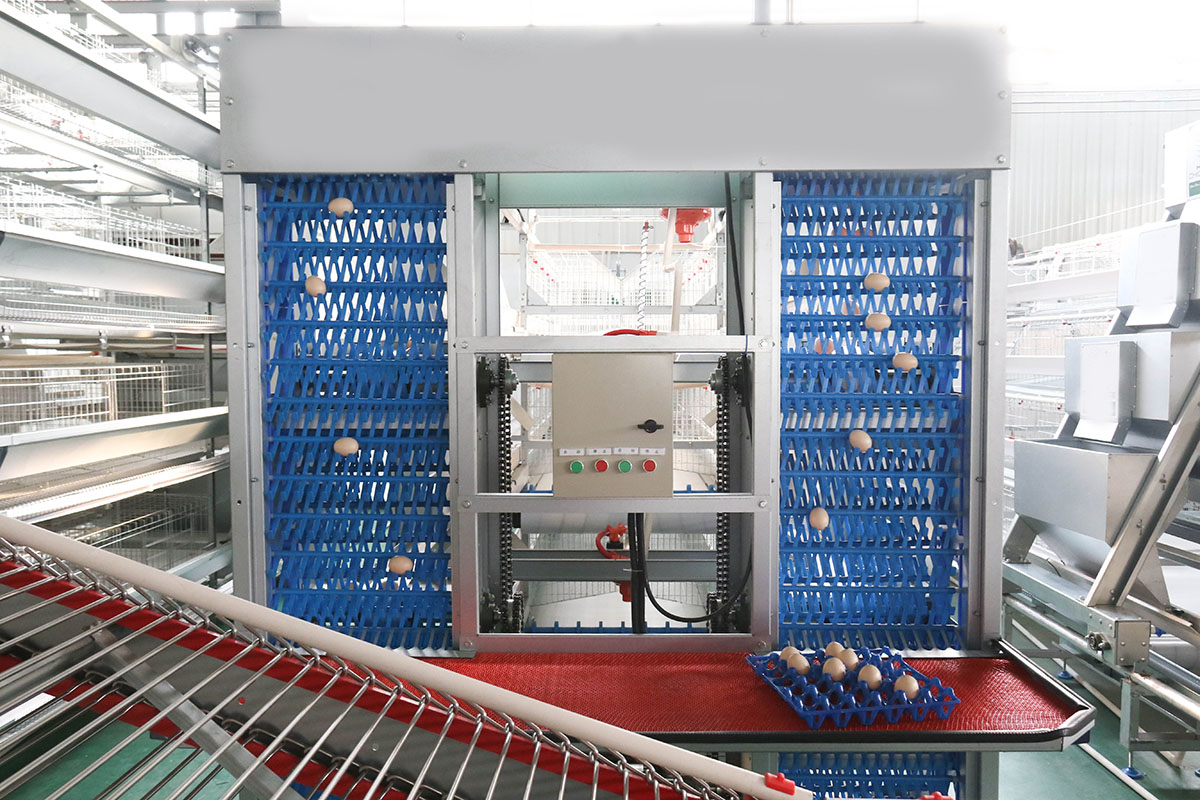

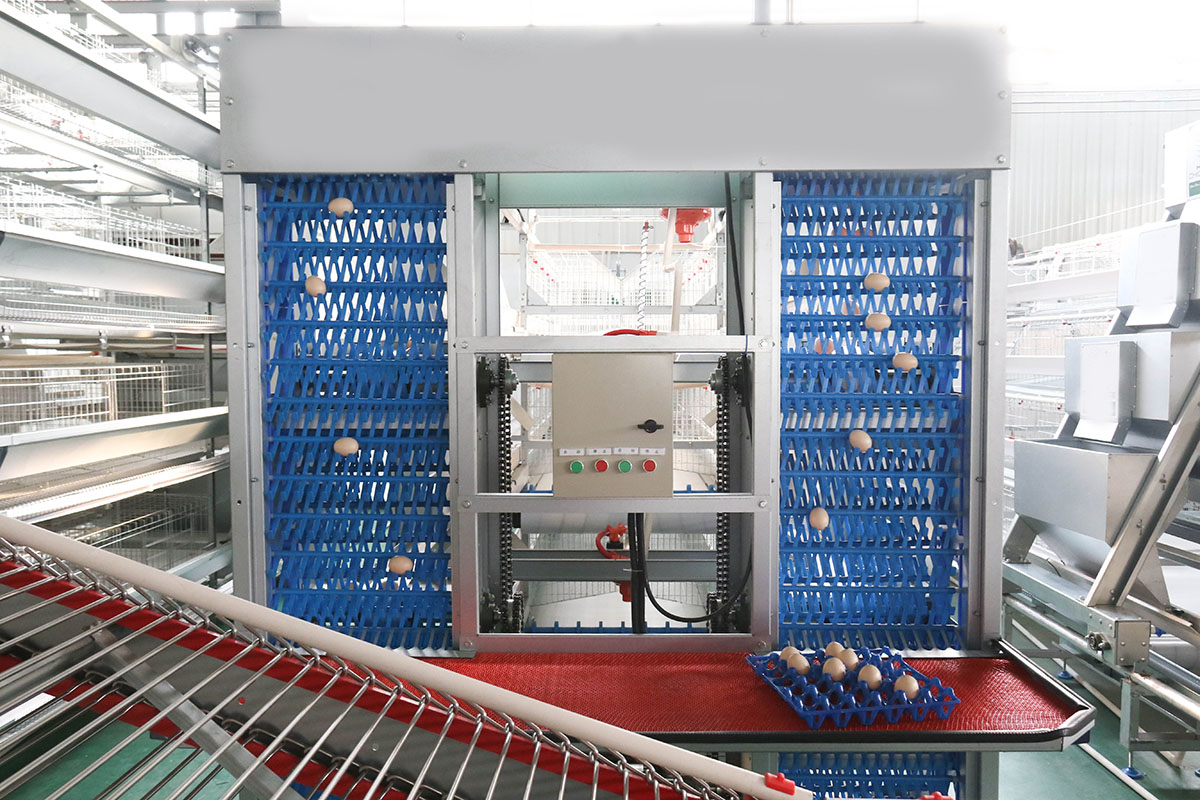

Components of the Automatic Poultry Egg Collection System

Components of the Automatic Poultry Egg Collection System

Automatic poultry egg collection system include various devices and other elements:

Automatic poultry egg collection system include various devices and other elements:

Import device that transports the eggs to the machine

Device that picks up the eggs

Guiding device

A buffer device

A transmission device

Buckle chain gear and lifting chain

Detailed introductions are also included

Composition of egg collecting machine

Composition of egg collecting machine

Base of the machine is made from high quality steel. Its chassis was designed by engineers who have many years of experience in structural design. The structure has a large carrying capacity that prevents structural deformation.

The egg upload system operates with transmission efficiency that incorporates a gear speed reduction drive. It has a low failure rate, has a long service life, operates with low noise, and reduces the negative effects of noise on the chickens.

The egg filtration system prevents any broken eggs from being uploaded into the system.

The egg belt and belt drive system is used to efficiently set the eggs using the gear speed reducer drive and so ensure that when the eggs are on the conveyor belt it runs smoothly. The drive roller is made of high quality rubber that increases friction with the conveyor belt.

There is a front-end poultry egg collection system. This ensures that the eggs don’t roll out of the system.

The power distribution system is equivalent to that used for national standard electric appliances and was produced from a professional electrical engineer’s design. It can also be designed according to user needs in terms of the electrical control system required.

Egg Collection Belt

Egg Collection Belt

The egg collection belt is made from high endurance polypropylene and is manufactured in white or in a gray color. It can be personalized in various ways, for example with red, yellow, blue and green lines.

Polypropylene is extremely resistant to bacteria and fungus, and even without any surface treatment it is resistant to corrosion. Because polypropylene does not absorb water it will not be affected by sudden changes in humidity and temperature. It is also resistant to UV and is an anti-static material that can be stitched or welding ultrasonically to widths of up to 50 mm and 70 mm. Once on the conveyor belt eggs are less likely to break.