| Introduction | Specification | 1000p/h egg tray production line |

Introduction

Introduction

Pulp egg tray making machine are used to produce a range of pulp molded products including egg trays, egg boxes, fruit trays, and coffee trays.

The material used for molded pulp products is waste paper, corrugated paper, waste newspaper, and old magazines.

Pulp molding egg tray machine can be made using 4 or 8, 12 faces rotating drums and each surface can incorporate 2, 3, 4, or 5 pieces moulds as required.

Production Line

Production Line

The production line includes a pulp making system, an egg tray molding system, an egg tray drying system, and an egg tray packing system.

1. Pumping system

This incorporates a hydrapulper, a pulp pump, an air compressor, agitator, a self priming pump, and a pulping machine.

2. Molding System

The forming system involves a fully automatic egg tray forming machine, a vacuum pump, a high-pressure washer, a negative pressure tank, mould, transfer mould, and a baler.

Usually, the mold material is plastic and it can be customized in various ways to form different shapes for wine or fruit trays, industrial packaging, for flower pots, and for disposable bowls.

3. Drying system

There are various drying options:

1. If the capacity is small, the egg tray can be air-dried.

2. A brick kiln drying system requires the least investment, making it the most economic and the highest efficiency production line. It is suitable for most countries except those where brick is expensive.

3. Metal drying may be used where brick kilns are too expensive. Single layer metal drying is easy to install and it looks attractive.

4. Multi layer drying is done in six layers so it does not require much space. It is a fully automatic production process that is easy to install. It is particularly well suited to workshops where space is limited.

Floor Plan Of Egg Tray Making Machine

| Specification of the egg tray machine | |||||

| Type | ZT-3×4 | ZT-3×8 | ZT-4×4 | ZT-4×8 | ZT-4×12 |

| Capacity | 2000pcs/hr | 2500pcs/hr | 2500pcs/hr | 5000pcs/hr | 6000pcs/hr |

| Workshop Requirement | ≥100 M2 | ≥100 M2 | ≥150 M2 | ≥150 M2 | ≥150 M2 |

| Electricity Consumption | 30-55KW | 30-55KW | 40-60KW | 80-110KW | 180-270KW |

| Material Consumption | 110-120 kg/hr | 130-150 kg/hr | 150-160 kg/hr | 240-320 kg/hr | 290-380 kg/hr |

| Worker Requirement | 3-4 | 4-5 | 4-5 | 5-6 | 5-6 |

| 1000p/h egg tray production line | ||||

| Equipment name | Model | Quantity | Pictures | Motor power |

| Forming System | ||||

| Forming machine | PT-1000 | 1set |  |

2.2KW |

| solenoid valve | 2w-20 , 220V | 2pcs |  |

|

| Speed Controller | JDIA-30 | 1pcs |  |

|

| Ball valve | DN15 | 2pcs |  |

|

| Black rubber hose | 1inch | 3m |  |

|

| Proximity switch | LJ18A3-8-J/EZ | 4pcs |  |

|

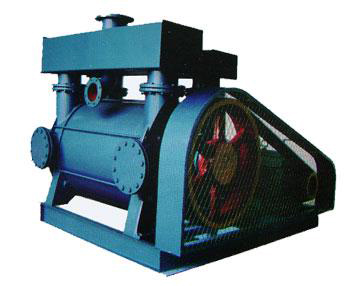

| Vacuum pump | ZKB-13 | 1set |  |

7.5KW |

| High pressure washer | 380Model | 1set |  |

2.2kw |

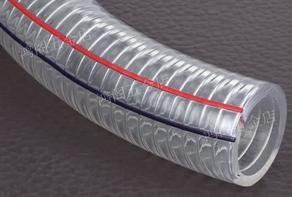

| steel wire pipe | 90# | 1roll |  |

|

| 60# | 1roll | |||

| 15# | 1roll | |||

| Air compressor | 0.9m³ | 1set |  |

5.5KW |

| Cleaning machine for mold | 380Model | 1set |  |

3KW |

| Pulping System | ||||

| Hydrabrusher | 1m³ | 1set |  |

7.5KW |

| Butterfly | DF100 | 1pcs |  |

|

| Pulp pump | 4inch | 1set |  |

3KW |

| waste paper pump | 11Model | 1set |  |

0.75kw |

| Pulp refiner | 120Model | 1sets |  |

2.2KW |

| Discharge pipe+butterfly valve | 114/100 | 1set |  |

|